Complete Guide on How to Install Cylindrical Roller Bearing Properly [Works Quickly]

- Share

- Issue Time

- Jul 24,2018

Summary

The cylindrical roller bearing is a kind of radial bearing and its rolling elements are cylindrical rollers. Its internal adopts a parallel structure.

![Complete Guide on How to Install Cylindrical Roller Bearing Properly [Works Quickly]](https://icdn.tradew.com/file/201804/1572758/jpg/6849931.jpg?x-oss-process=image/quality,Q_90)

Complete Guide on How to Install Cylindrical Roller Bearing Properly [Works Quickly]

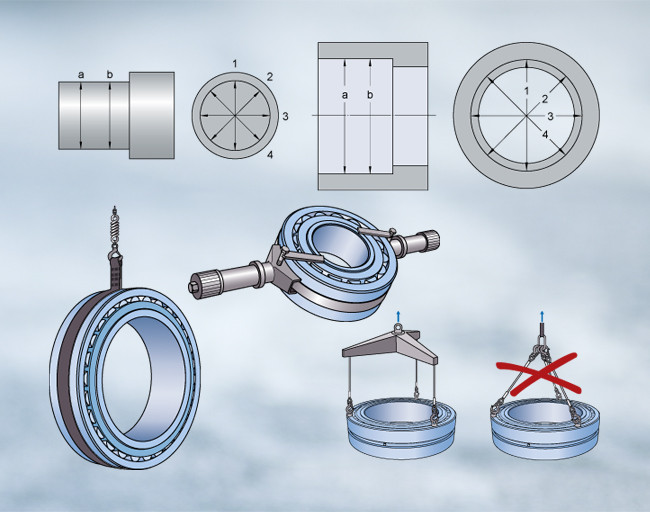

The cylindrical roller bearing is a kind of radial bearing and its rolling elements are cylindrical rollers. The internal structure of the cylindrical roller bearing adopts rollers arranged in parallel. There are retainers to separate each roller, which can prevent the tilting of the rollers or the friction between the rollers, and effectively prevents the increase of the rotating torque.

Cylindrical Roller Bearing Installation Process

Whether the bearing installation correctly or not affects precision, life, and performance. Therefore, the design and assembly department should fully study the installation of bearings. You want to install according to the job criteria. The standard operating items are usually as follows:

(1) Clean the bearing and bearing connection parts;

(2) Check the size and precision of the bearing connected parts;

(3) Install bearings;

(4) Inspect after installing the bearing;

(5) Provide lubricants to the bearing.

Installation Precautions

You better not to open the bearing package before installation. General grease lubrication, do not clean, directly fill the grease. When you lubricate bearings with lubricants, also you do not need to clean commonly. But high-speed bearing in the equipment you should clean with clean oil and remove the anti-rust coating on the bearing. The bearing without the anti-rust agent is easy to rust, so you can not place it. In addition, don't clean the grease sealed bearing for direct use.

The method of bearing installation varies with bearing structure, fit, and conditions. Generally, you need to over-fill the inner ring due to the rotation of the shaft. Cylindrical bore bearings always need to press in or use the heat installation method. For tapered holes, install directly on the tapered shaft or sleeve installation.

When you install it into the shell, there is usually more clearance fit. The outer ring is overfilled, it is usually pressed by the press, or there is a method of cold shrinkage fit after cooling. Using dry ice as a coolant, the moisture in the air will condense on the surface of the bearing when it is cooled and fitted. Therefore, appropriate anti-rust measures are needed.