3 Main Reasons on What Cause Bearing Failure 2020 [Quick]

- Share

- Issue Time

- Aug 21,2018

Summary

Bearing failure, in the narrow sense, refers to the failure to meet the predetermined task. And broadly it includes the case where it can run.

![3 Main Reasons on What Cause Bearing Failure 2020 [Quick]](https://icdn.tradew.com/file/201804/1572758/jpg/6873135.jpg?x-oss-process=image/quality,Q_90)

3 Main Reasons on What Cause Bearing Failure 2020 [Quick]

Bearing failure, in the narrow sense, refers to the failure to meet the predetermined task. And broadly it includes the case where it can run but the performance begins to deteriorate.

Contact fatigue bearing failure

Failure of bearing working surface under the action of alternating stress. Contact fatigue spalling occurs on the working surface of the rolling bearing, it often has fatigue cracks. It first occurs at the point below the contact surface where the maximum alternating shear stress is generated. And then extends to the surface to form different spalling shapes, such as pitting or pitting spalling, and spalling into small pieces called shallow spalling. As the flaking surface expands gradually. It tends to expand to the deep layer, forming deep spalling. Deep spalling is the source of contact fatigue failure.

The wear failure

Refers to the relative sliding friction between surfaces cause the metal constant wear. And the metal constant wear causes failure. Sustained wear will cause gradual damage to bearing parts and eventually lead to loss of bearing size accuracy and other related problems. Wear may affect the change of shape, an increase of clearance, and change of working surface topography. They may affect lubricant or contaminate it to a certain extent and cause complete loss of lubrication function. Thus causing loss of bearing rotation accuracy and even failure of normal operation. Wear failure is one of the most common failure modes of bearings.

Abrasive wear system

This refers to the wear between the working surfaces of the bearing, which is caused by the rubbing of foreign hard particles or hard foreign objects or metal surfaces and the relative movement of contact surfaces. Hard particles or foreign matter may come from inside the main engine or from other adjacent parts of the host system sent into the bearing by a lubricating medium.

Knowledge of bearing accuracy error. Adhesive wear refers to them because of the friction surface microscopic bumps or foreign bodies make the friction surface is uneven, serious deterioration, the condition of lubrication for local friction heat production, easy to cause local deformation and friction surface friction welded phenomenon, serious when the surface of the metal may be the partial melting. It will tear contact surface forces from the local friction welding points on the matrix and increase the plastic deformation. This adhesive - tearing - adhesive circular process constitutes adhesive wear. In general, slight adhesive wear is abrasion, and severe adhesive wear is a bite.

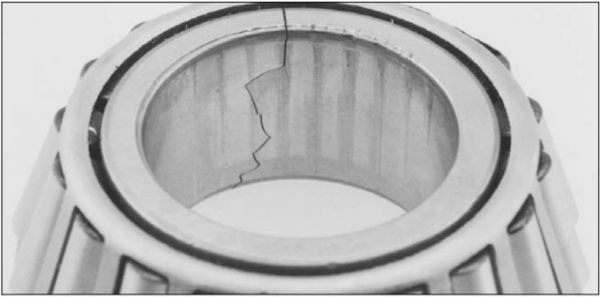

Bearing failure

The main reason is defect and overload. When the applied load exceeds the bearing material strength limit, the part fracture is overload fracture. The main reason for overload is the sudden failure of the main engine or improper installation. Defects such as micro-cracks, shrinkage holes, air bubbles, large foreign debris, overheated tissues, and local burns of bearing parts may also cause fracture at the defects when impact overload or severe vibration occurs.

In the process of bearing manufacturing, instruments can analyze the incoming inspection of raw materials, the quality control of forging and heat treatment, and the control of processing process correctly whether the above defects exist or not. And people must strengthen their control in the future. But generally speaking, the most common bearing failure is overload failure.

External factors

Bearing in the work, due to the influence of external or internal factors, the original matching clearance changes, the accuracy decreases, and even causes "bite dead" is "clearance change failure. External factors such as excessive interference, improper installation, expansion caused by temperature rise, instantaneous overload, etc.

- I get good lubrication, and cut off the right moisture and debris, said oil seal should not wear. However, when open the bearing box, best check bearing and periodically check the oil seal. Check of the condition of the near the bearing oil seal, to ensure that they are enough to prevent hot corrosion along the axis of the liquid or gas into liquid or bearing, oil seal already wears should be replaced as soon as possible.

- High temperatures often indicate that the bearing is already in an abnormal condition. High temperatures are also harmful to the lubricant inside the bearing. Sometimes the overheating of the bearing can be attributed to the lubricant of the bearing.

- Causes of high-temperature bearings include insufficient or excessive lubrication, a lubricant containing magazines, excessive load, bearing damage, insufficient clearance, and high-temperature friction from oil seals.

- Check the status of the machine in operation and monitor it, so as not to cause equipment shutdown.