NTN Developed The Bearing "Portable Anomaly Detection Device II"

- Share

- Issue Time

- Aug 5,2019

Summary

NTN Corporation has developed a "portable abnormality detecting device II" that can detect bearing abnormalities by simple operation using long-term bearing diagnostic technology and vibration analysis technology.

NTN Developed The Bearing"Portable Anomaly Detection Device II"

NTN Corporation has developed a"portable abnormality detecting device II" that can detect bearingabnormalities by simple operation using long-term bearing diagnostic technologyand vibration analysis technology.

In 2014, NTN developed a "portableanomaly detection device" that can calculate, analyze, and display resultsusing the vibration data of the Android terminal, and made a customer proposal.At the same time as the customers have received favorable comments, the markethas also raised the need for environmental protection to further improveusability, miniaturization, dustproofness, and water repellency.

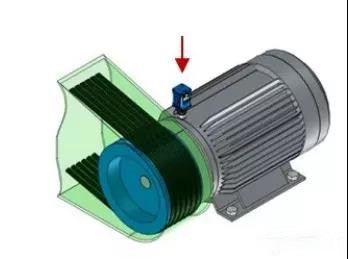

In the past, the product was a split typein which the main body and the measuring terminal were wired. The developmentproduct of this time is unitized on the body and the measurement site, whichimproves usability and achieves miniaturization. Dust-proof and waterproofpatterns can be used even next to equipment where dust and coolant splashduring processing. In addition, it can be charged by USB cable for long-termmeasurement.

The measured vibration data is sent to thesmart device on which the dedicated APP is installed, and the bearing isabnormally analyzed by OA*1 and FFT*2. When the bearing is abnormal, thedamaged part of the bearing can also be determined. The time spent on eachmeasurement is also reduced to 1/10 of the original by the rational design ofthe wireless communication part. The measurement results can be saved at theterminal, the measurement history is represented by a graph, and it can also beused for continuous monitoring of the condition of the equipment.

In addition to developing high-quality andhigh-performance bearings, NTN also strengthens bearing diagnostics, analyticaltools and diagnostic technology services, and provides technical proposals forextending the total life cycle of equipment, reducing downtime and improvingproduction efficiency. To expand services and solve problems.

In addition, this development product wasexhibited at the 29th Japan International Machine Tool Show (JIMTOF2018) heldin Tokyo from November 1st to 6th, 2018.

1.OverAll The total value of the amplitudeof each vibration frequency component of acceleration, velocity, anddisplacement.

2. A method for obtaining a spectrum,analyzing and parsing an input signal using a Fast Fourier Transform.