20 Steps To Replacing Your Trailer Wheel Bearing

- Share

- Issue Time

- Aug 23,2019

Summary

Trailer wheel bearings must be changed fairly regularly to keep your trailer running smoothly. As a general rule, if your wheel bearings are noisy, it’s probably time to change them.

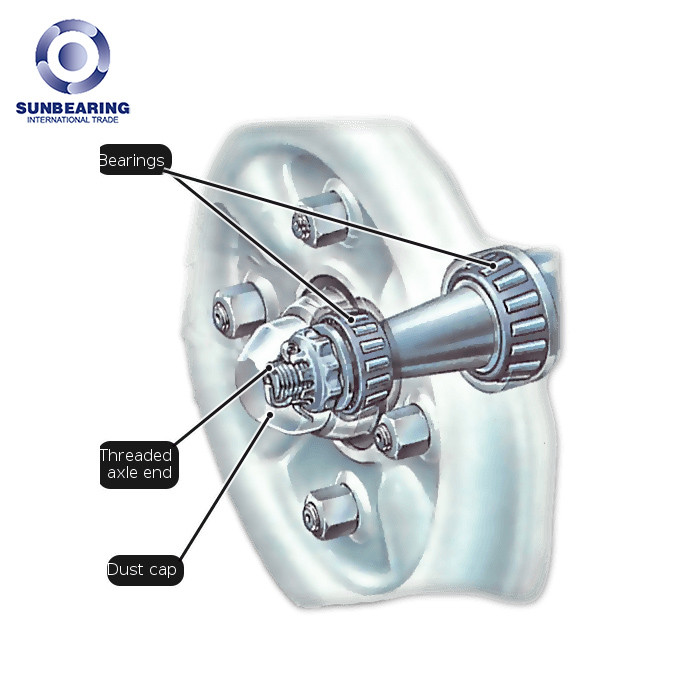

20 Steps To Replacing Your Trailer Wheel Bearing

Trailer wheel bearings must be changed fairly regularly to keep your trailer running smoothly. As a general rule, if your wheel bearings are noisy, it’s probably time to change them.

1. Remove the trailer’s wheel as normal

2. On a flat surface, remove the dust cap, cotter pin, adjusting nuts and washers

3. Carefully pull the hub towards you, so that the outer bearing does not fall out. You will notice that the inner bearing and seal will remain attached to the hub. This is normal

4. Remove the outer bearings from the hub

5. Wipe off the old lubricant or grease from the spindle and hub assembly

6. Clean the hub assembly and spindle with kerosene or solvent. It is best to do this in an empty container to ensure a thorough clean

7. Using a hammer and punch, remove the inner bearing and seal from the hub

8. Evenly spread a light coating of grease on the spindle shaft. This will assist the installation and cooling process

9. Inspect the hub bore and backing shoulder. Use sandpaper to remove any knicks and burrs

10. Remove the new bearings from the packaging and immediately cover with grease. Be sure to force grease under the cage and between the rollers

11. Fill the hub’s inside diameter with grease

12. Pop the inner bearing into the hub

13. Install the seal, ensuring that the seal lips are facing the right direction. Lightly tap the seal with a hammer to ensure it's installed properly, taking care not to damage the seal

14. Insert the grease-packed outer bearing, washer, and adjusting nut. Smooth out the grease

15. Carefully slide the hub assembly back onto the spindle, so that none of the components are damaged

16. Tighten the adjustment nut as you turn the wheel until there is resistance

17. Turn the adjustment nut back one-quarter of the way with your wrench

18. Lock the nut with your new cotter pin

19. Replace the dust cap with the hammer and punch. Ensure that it is securely seated against the hub shoulder

20. Put the wheel back on the trailer as normal