Complete Instruction on How to Set Rolling Bearing Clearance

- Share

- Issue Time

- Oct 27,2020

Summary

Rolling bearing clearance adjustment and preload is an important part of the rolling bearing assembly work which can extend bearing life.

Complete Instruction on How to Set Rolling Bearing Clearance

Rolling bearing clearance adjustment and preload is an important part of the rolling bearing assembly work. Accurately grasp the process concept of clearance adjustment and preloading is very important. And use this processing method correctly in the assembly work is the guarantee of the quality of the bearing assembly work.

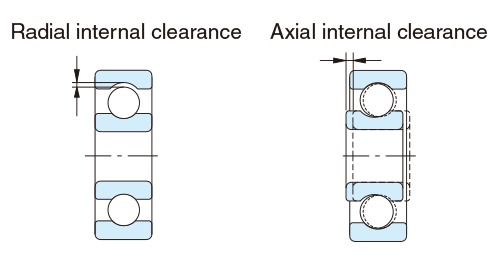

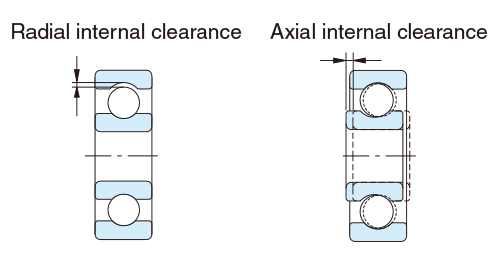

The clearance of a rolling bearing refers to the maximum amount of movement of the other ring in the radial or axial direction. There are two types of clearance: radial clearance and axial clearance.

Clearance During The Bearing Installation

When you assemble rolling bearings, you should better make sure the bearing clearance properly. If the clearance is too large, the number of rolling elements bearing the load at the same time will decrease. And it will increase a single rolling element load thereby reducing the rotation accuracy of the bearing.

If the clearance is too small, it will increase the bearing friction, the heat generated, and the bearing wear. Therefore, it will reduce the bearing service life. Thus, you must strictly control and adjust the clearance of bearings during assembly.

Bearing Preload

How to Adjust Rolling Bearing Clearance

It is necessary to ensure good lubrication and heat dissipation while adjusting the clearance or preload. If you improperly adjust or poorly lubricate bearing, it will in turn increase bearing wear and reduce bearing life.

The adjustment and pre-load of the clearance are usually done by making the inner ring of the bearing an appropriate axial relative displacement to the outer ring.

Assembly technical requirements

The adjustment of the rolling bearing clearance can effectively improve the rotation accuracy of the bearing, increase the bearing capacity of the bearing, and extend the service life of the bearing. At the same time, it can effectively reduce vibration and noise. However, not all rolling bearings require clearance adjustment during assembly. Pre-load can certainly improve bearing rigidity and spin accuracy, but at the same time it will increase friction. It will destroy the lubricating oil and generate a lot of heat. Therefore, the preloaded bearing must be forced to lubricate and cool.

This process method is only used when the rigidity and rotation accuracy of the bearing are extremely high. It is a relatively special process. Whether to adjust the clearance and pre-tighten during the assembly of rolling bearings. According to the assembly technical requirements proposed in the technical documents to decide.

To meet the requirements of clearance adjustment and preload under thermal equilibrium conditions

The actual ideal working gap of a rolling bearing is the gap after the bearing temperature rises stably. Therefore, the adjustment of bearing clearance has two stages. First, adjust the bearing clearance at room temperature in accordance with relevant operating specifications and technical requirements. Then, loosen the adjustment mechanism appropriately. Carry out dry run test, from low speed to high speed no more than 2 hours. The idling time at the highest speed is not less than 30min. The bearing should run flexibly, with low noise, and the working temperature should not exceed 50℃. Finally, reset and lock the adjustment mechanism.

Good lubrication for bearings

Good lubrication can not only reduce friction, but also has a cooling effect on bearings and shaft parts. After adjusting the rolling bearing clearance, the friction will increase, and the heat generated will increase the temperature of the entire transmission system. If it can not dissipate the heat in time, the heat will change the size of the transmission parts, thus affecting the change of the clearance of the rolling bearing.

For rolling bearings with clearance adjustment, good lubrication must be maintained to reduce friction. What's more important is the use of continuously circulating lubricating oil to take away a lot of heat, control the temperature rise, and achieve the thermal balance of the transmission system.