SUNBEARING Cylinder Roller Bearing FC6084218 Silver 300*420*218mm Chrome Steel GCR15

- Model

- FC6084218

Review

Description

Product Description

| Cylinder Roller Bearing FC6084218 | |

|---|---|

| Specification | |

| Design Units | Metric |

| Structure | Roller Bearing |

| Weights | 93.2kgs |

| Cage Material | Steel Cage.Brass Cage.Nylon Cage |

| Material | Chrome Steel GCR15 |

| Ball Type | Steel Roller |

| Seals Type | Open |

| Certificate | ISO9001:2008 |

| Feature | High precision, high load resistance, and durable, quality assurance. |

| Number of Row | Four |

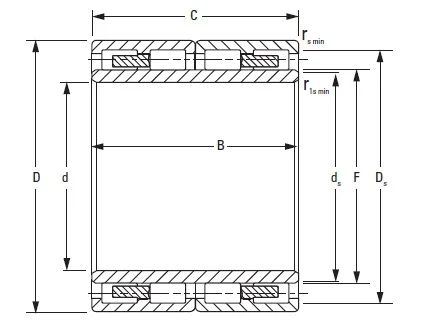

| Dimensions | |

| d-Bore Diameter | 300mm |

| D-Outer Diameter | 420mm |

| Precision Rating | P0 P5 P4 P6 P2 |

| Clearance | C2 C3 C4 C5 C0 |

| H-Total Width | 218mm |

| Basic Load Ratings | |

| Cr Dynamic Load Rating | 275000N |

| C0r Static Load Rating | 310000N |

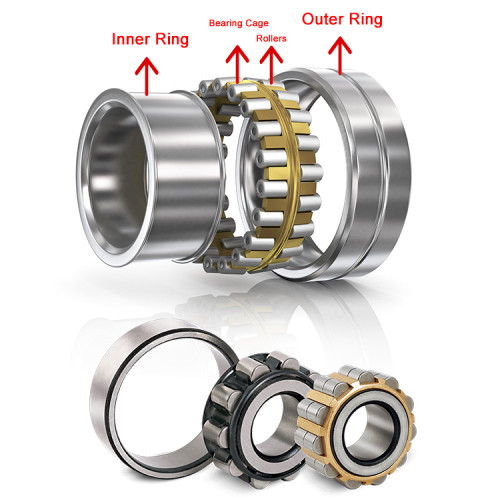

FC6084218 Four Row Rolling Mill Bearing

Product Description

SUN Bearing’s four-row cylindrical roller bearings are designed for the rigors of daily use in applications where moderate and high speeds, high radial loads, elevated temperatures and debris are constant challenges. Designed with well-balanced cross sections, these bearings provide high-radial-load capacity within the bearing envelope.

The radial internal clearance for the bearing assembly must be included when ordering either a) the complete assembly or b) with the inner-ring set. It is advisable to order the inner-ring set independent of the outer ring set when the final grind of the inner-ring O.D. is accomplished after mounting on the roll neck.

The bearing style incorporates two outer races with triple flanges (solid ribs). The inner race is usually single-piece construction. The outer assemblies consist of the outer race, rollers and cages, which create a unitized construction. Handling is made simple by this design. A loading slot is used for roller insertion. Lubrication is generally accomplished via slots in the faces of the outer ring. The cage is single-piece, fully machined brass or steel material. The roller pockets are staggered between the races.

· Two outer rings with integral ribs.

· Two inner rings.

· With lubrication grooves and holes on outer rings.

· Without lubrication grooves and holes on outer rings.

· Two solid-steel or brass cages.

Product picture&2D Drawing of FC6084218 Four Row Rolling Mill Bearing

Application Fields

Engineered primarily for rolling mill roll-neck applications,SUN Bearing’s four-row cylindrical bearings are commonly used in work roll or back-up roll positions in flat product, long productand structural mills.

1.Product Features

· Available in sizes 140 mm I.D. – 2000 mm

· Case-hardened rings and rollers enhance durability.

· Inner races are interchangeable with outer assemblies.

· Manufactured to P6 boundary and P5 run out tolerances.

· Roller profiles are custom designed and manufactured for optimum performance.

· Straight and tapered bores are available.

2.Radial Internal Clearance

SUN Bearing's standard bearings offer different clearances, such as C3 or C4 according. If needed for your application,they can be furnished with a tapered bore.

Supply inner rings in two ways: a finished state with no additional grinding required or a semi-finished condition with appropriate grind stock. Semi-finished inner rings allow mill operators to optimize the roll’s precision by finish grinding the inner ring after mounting it onto the roll.

3.Lubrication

SUN Bearing's four-row cylindrical roller bearings can be used with grease, oil-air, oil-mist or circulating-oil systems. The bearings must be correctly lubricated for maximum performance through either lubrication grooves, holes in the outer-ring or through integrated face slots on the outer-ring faces.

4.Material

Our bearings are designed to provide superior size stability,fracture toughness and reliability. By using only high quality,carburized alloy, and applying a special heat-treatment duringthe manufacturing process, we are able to produce bearings that can withstand the heavy stresses and impact loading often experienced by multi-row cylindrical roller bearings used in rolling mills.

5.Mounting design and fitting prctice

The cylindrical roller bearing design accommodates radial loading only, therefore, a separate thrust bearing must be usedto provide axial shaft location.

The housing fitting practice usually results in a loose fit to facilitate easy removal at regular maintenance intervals. The preferred shaft fit is tight. There are occasions where loose shaft fits are tolerated, such as on some roughing-mill equipment. In the cases where a shaft fit is loose, inner-race bore lubrication grooves must be incorporated in the bearing.

Inner rings can be ordered separately from the outer assembly in order to equip additional spare rolls. Inner- and outerring assemblies are interchangeable in regard to internalclearance.