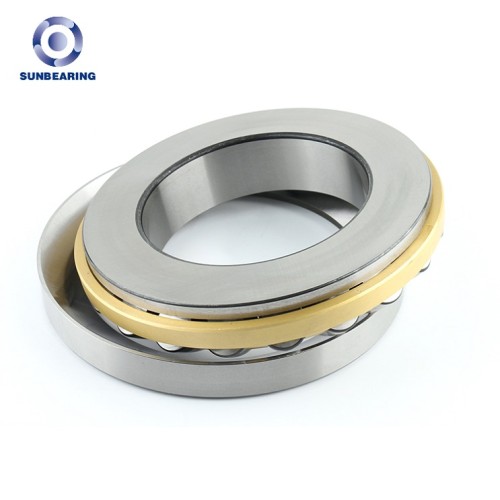

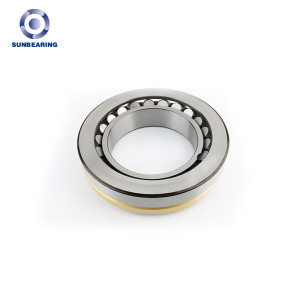

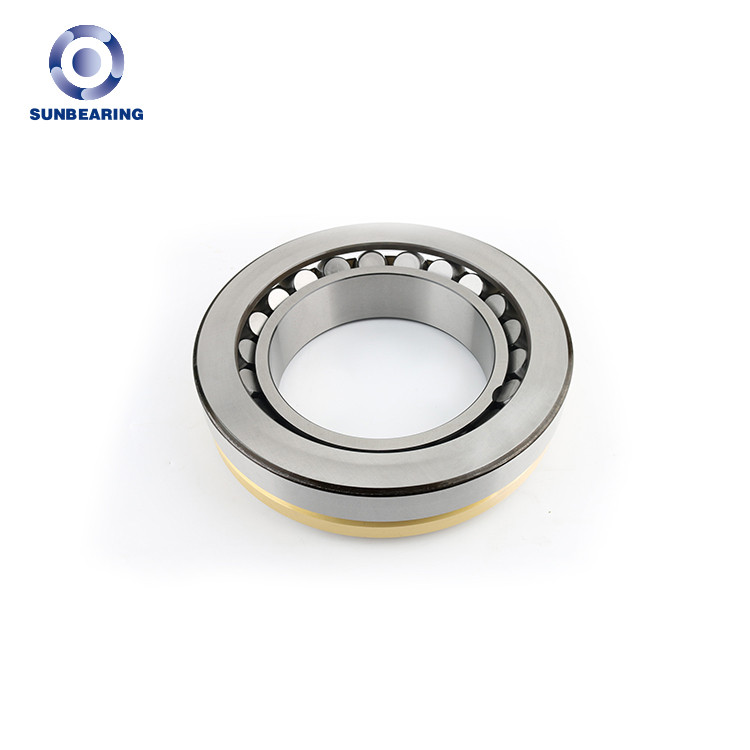

292/800 Spherical Roller Thrust Bearing Yellow and Silver 800*1060*155mm Chrome Steel SUNBEARING

- Model

- 292/800

Review

Description

Product Description

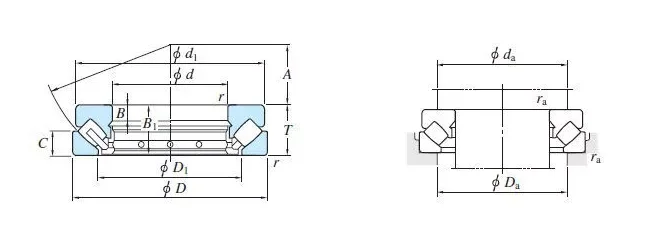

| Thrust Aligning Roller Bearing 292/800 | |

|---|---|

| Specification | |

| Design Units | Metric |

| Structure | Roller Bearing |

| Weights | 343kgs |

| Cage Material | Steel Cage.Brass Cage.Nylon Cage |

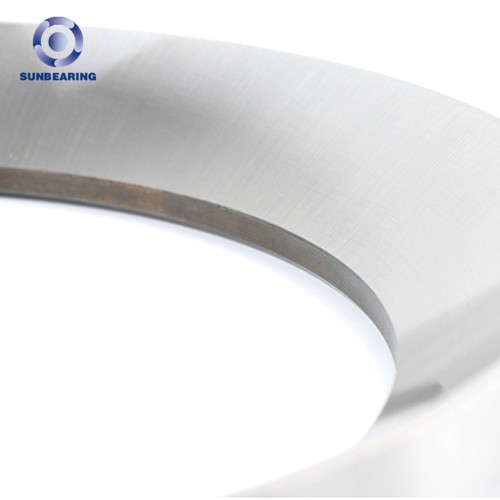

| Material | Chrome Steel GCR15 |

| Ball Type | Steel Roller |

| Seals Type | Open |

| Certificate | ISO9001:2008 |

| Feature | They can be supplied with or without radius roller grooves in the rings. |

| Number of Rows | Single |

| Dimensions | |

| d-Bore Diameter | 800mm |

| D-Outer Diameter | 1060mm |

| Precision Rating | P0 P5 P4 P6 P2 |

| Clearance | C2 C3 C4 C5 C0 |

| H-Total Width | 155mm |

| Basic Load Ratings | |

| Cr Dynamic Load Rating | 46000N |

| C0r Static Load Rating | 47000N |

292/800 Thrust roller bearings consist of two precision chrome steel washers (ring) and a roller complement spaced by bronze retainer. They can be supplied with or without radius roller grooves in the rings. Thrust bearings are used under purely axial loads. Bearing rings mounted on the shaft are called shaft washers, and those mounted in the housing are called housing washers. Both washers contain raceways for the rollers.

High-quality thrust ball bearings

This type of bearings are designed for axial load first, their contact angle range between 300 to 900.These bearings can be differentiated by the type of rolling element which are same as transverse bearings, such as balls used in thrust bearings, roller used in thrust roller bearings.

Products Application:

For the bearings, they can be used in many machines, like the Medium and large motors,electric generator, internal combustion engine,gas turbine,machine tool spindle,reduction gear,mill handling machine and other kinds of industrial machinery.

Method of extending the thrust roller bearing’s lifetime:

1. The installation is correct, that affects precision, life, performance. And fill the bearing with lubricant after installation.

2. Don't allow strong impact, such as hammer striking, transfer roller pressure

3. Use the accurate installation tool, avoid to use cloth kind and short fibers

4. Lubricate the bearing to avoid rust with high quality mineral oil, especially in summer

5. General inspection, such as the surrounding temperature, vibrate, noise inspection

6. Keep bearing cleaning from dirt, dust, pollutant, moisture.

7. Bearing should not be ultra cooled.