SUNBEARING Cylindrical Roller Bearing NU1030 Silver 150*225*35mm Chrome Steel GCR15

- Model

- NU1030

Review

Description

Product Description

| Cylindrical Roller Bearing NU1030 | |

|---|---|

| Specification | |

| Design Units | Metric |

| Structure | Roller Bearing |

| Weights | 4.77kgs |

| Cage Material | Steel Cage.Brass Cage.Nylon Cage |

| Material | Chrome Steel GCR15 |

| Ball Type | Copper Roller |

| Seals Type | Open |

| Certificate | ISO9001:2008 |

| Feature | The friction coefficient is small, suitable for high speed. |

| Number of Rows | Single |

| Dimensions | |

| d-Bore Diameter | 150mm |

| D-Outer Diameter | 225mm |

| Precision Rating | P0 P5 P4 P6 P2 |

| Clearance | C2 C3 C4 C5 C0 |

| H-Total Width | 35mm |

| Basic Load Ratings | |

| Cr Dynamic Load Rating | 202000N |

| C0r Static Load Rating | 294000N |

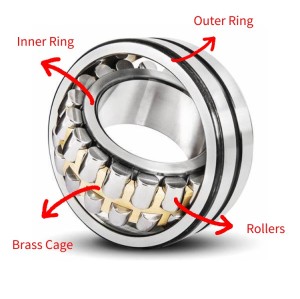

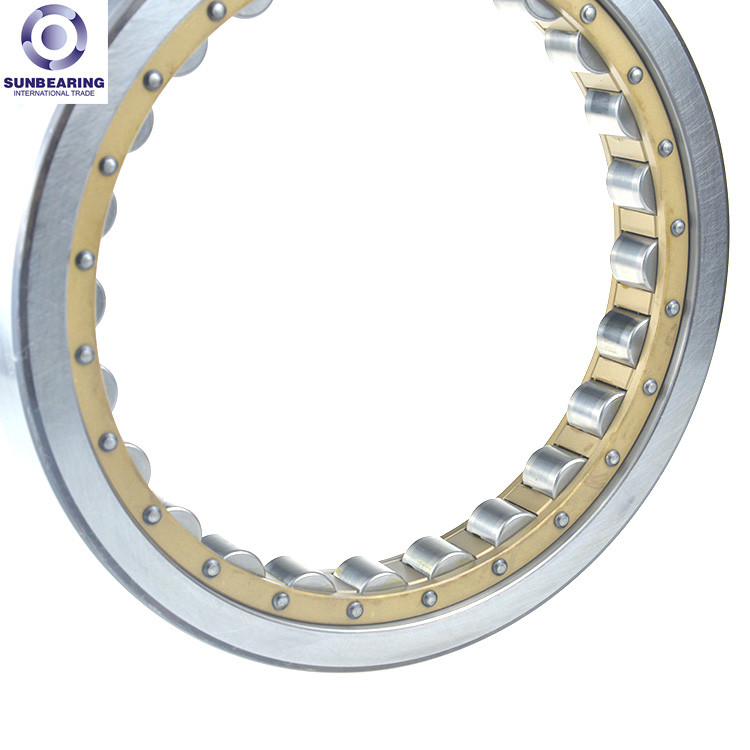

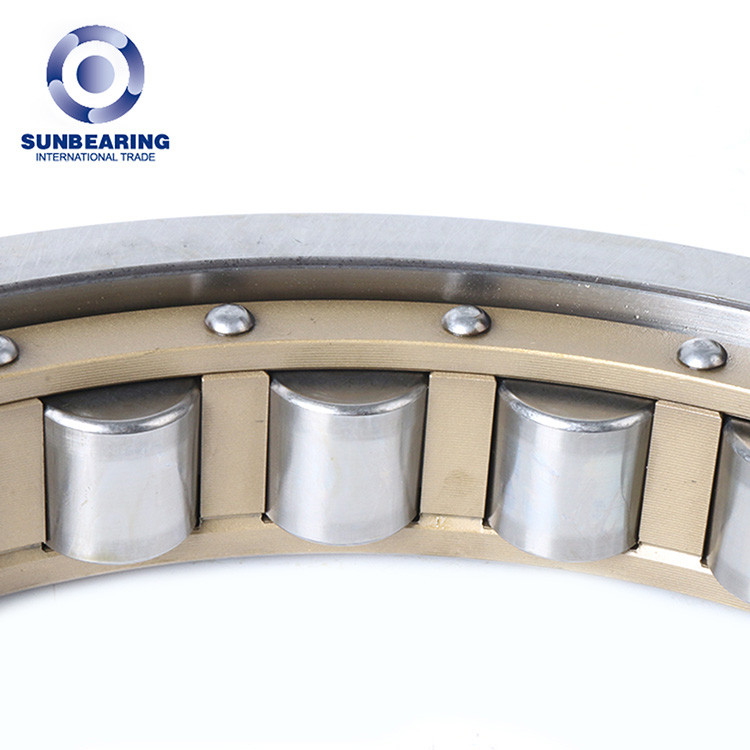

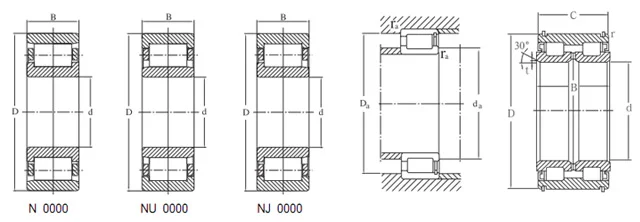

The most advanced technological process is adopted in the production of products. The raceway has convexity, fine appearance, high precision reserve, and long service life. There are EM-type brass solid holders and E-type combination holders. Stamping steel plate holder, TN nylon holder, NU type, NJ type, NUP type, NF type, RN type, RNU type, RNN type, RNL type, NCL type, NCF type, SL type, and other varieties of bearings technological process is adopted in the production of products. The raceway has convexity, fine appearance, high precision reserve, and long service life. There are EM-type brass solid holders and E-type combination holders. Stamping steel plate holder, TN nylon holder, NU type, NJ type, NUP type, NF type, RN type, RNU type, RNN type, RNL type, NCL type, NCF type, SL type, and other varieties of bearings

The cylindrical roller bearing is of high load capacity and can operate at high speeds because they use rollers as their rolling elements. They can therefore be used in applications involving heavy radial and impact loading.

The rollers are cylindrical in shape and crowned at the end in order to reduce the stress concentrations. They are also suitable for applications that require high speed because the rollers are guided by ribs that are either on the outer or inner ring.