6808 Thin Section Deep Groove Ball Bearing 40*52*7mm Single Row SUNBEARING

- Model

- 6808

Item specifics

- Color

- Silver

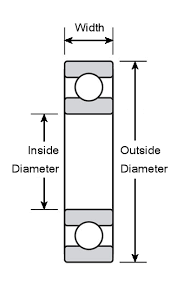

- Inner Diameter

- 40mm

- Outer Diameter

- 52mm

- Width

- 7mm

Review

Description

6808 Thin Section Deep Groove Ball Bearing 40*52*7mm Single Row SUNBEARING

|

Bore diameter:

|

40 mm

|

Basic dynamic load rating

|

4,923 N |

|

Outside diameter:

|

52 mm

|

Basic static load rating

|

4,178 N |

|

Overall width:

|

7 mm

|

Max Speed (Grease)

|

12,000 rpm |

|

Rows of Balls

|

Single

|

Ball Qty

|

21 |

|

Outer ring type:

|

Unsplit

|

Ball Dia (Dw)

|

3.5 mm |

|

Radial clearance class

|

C0 Standard Clearance

|

Mass

|

0.035 kg |

|

Closure type:

|

2RS

|

Max. Shaft Shoulder Dia. Inner (Ui)

|

43.2 mm |

Material | Chrome Steel | Min. Housing Shoulder Dia., Outer (Uo) | 48.99 mm |

Cage Material | Sheet Steel | Precision | A1 |

Radius (min) (rs) | 0.3 mm | Factor f0 | 16.3 |

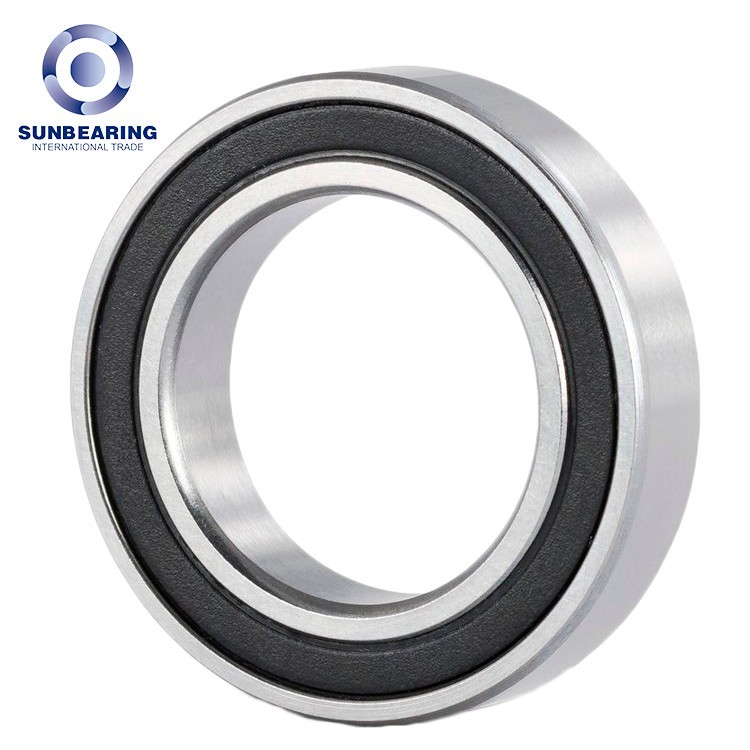

6808 Bearing Short Description

- Lubricant cannot be washed out

- Reduced risk of corrosion

- Larger lubricant reservoir

- Longer lubricant service life

Technical specifications:

Material: steel

Bearing Type: deep groove ball bearing 61808/6808

Material: 100Cr6 bearing steel

Dimension AØxIØxB: 40x52x7 mm

Seal: 2RS - double-sided grinding seal

Execution: Solid Oil technology

Silver

6808 Deep Groove Ball Bearing Material

6808 ball-bearing uses the polymer material. The polymer material is pressed into the free space of the bearing. This leaves a very small gap between the polymer and the rolling elements or the raceways, which allows the bearing parts to circulate freely. The polymer material has a sponge-like structure with millions of microscopic pores, which retain the lubricating oil due to the surface tension. In operation, the polymer matrix releases the lubricating oil into the small gap and thus ensures effective lubrication.

Note: When pressing in ball bearings, always make sure that the bearing is always pressed in via the outer ring, which is also the seat of the bearing.

Example hub: The hub body bearings are pressed in there via the outer ring. The bearing may therefore only be pressed in via the outer ring. Never over the inner ring.