Q: What is preloading in bearings?

- Share

- Issue Time

- Jan 8,2020

A: Bearing preload refers to the amount of axial or radial load pre-loaded to ensure the normal operation of the bearing, also known as preload.

The main purpose of high-speed precision spindle bearing preloading is to improve the rotation accuracy of the bearing, avoid the sliding of rolling elements at high speed, improve the rigidity of the bearing, reduce the amount of axial and radial movement of the bearing, increase bearing damping, reduce noise and improve bearing use life. Radial preload is generally achieved by adjusting the radial clearance of the bearing, and the purpose is to ensure the normal operation of the bearing.

Bearing preloading method:

1.Radial preloading method

The radial jacking method is often used in tapered bore bearings that bear radial loads. A typical example is a double-row precision short cylindrical roller bearing. The axial position of this bearing relative to the tapered journal is adjusted by a nut to make the inner The ring has a proper expansion amount to obtain a radial negative clearance. This method is mostly used in machine tool spindles and jet engines.

2.Axial pretensioning method

The axial preloading method can be roughly divided into positioning preloading and constant-pressure preloading.

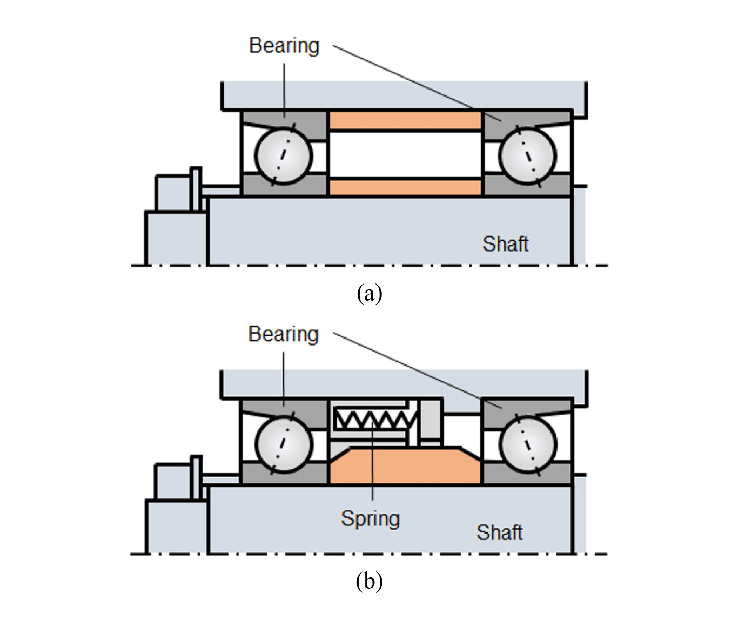

(1) In positioning preloading, the appropriate preload can be obtained by adjusting the size of the bushing or gasket; it can also be adjusted by measuring or controlling the starting friction torque; it can also be directly adjusted in advance The preloaded paired double bearings are used to achieve the purpose of preload. At this time, the user generally does not need to adjust again. In short, the relative position of any bearing that has been axially preloaded will definitely not change during use.

(2) Constant pressure preloading is a method of using bearings such as coil springs and disc springs to obtain appropriate preloading. The rigidity of the preloaded spring is generally much smaller than the rigidity of the bearing, so the relative position of the fixed-pressure preloaded bearing will change during use, but the preload amount is approximately unchanged.