Slide Bearing VS Ball Bearing How to Choose [Quick]

- Share

- Issue Time

- Nov 6,2018

Summary

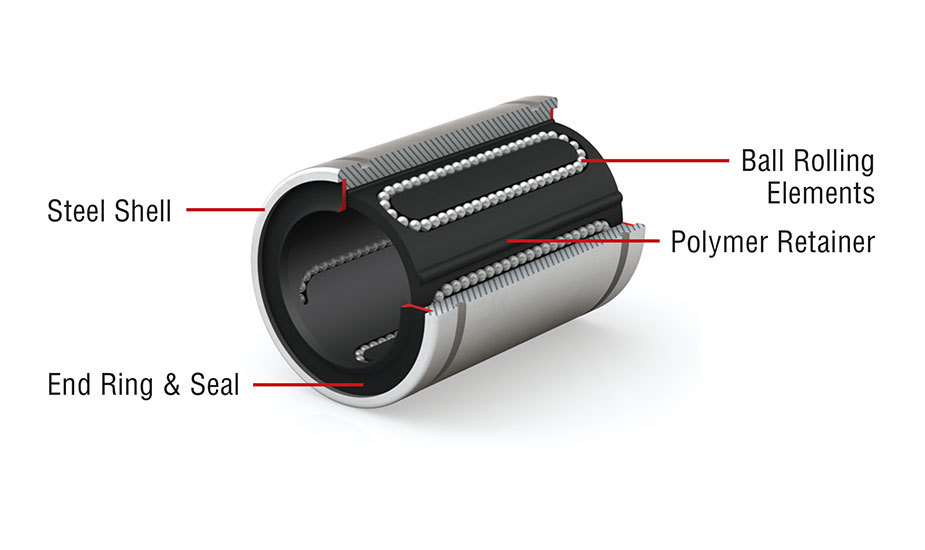

Slide bearing vs ball bearing, due to the contact between the balls, the ball bearings need to have lubrication. Therefore, this makes them more vulnerable.

![Slide Bearing VS Ball Bearing How to Choose [Quick]](https://icdn.tradew.com/file/201804/1572758/jpg/7400012.jpg?x-oss-process=image/quality,Q_90)

Slide Bearing VS Ball Bearing How to Choose [Quick]

The Development of Plastic Slide Bearing

Advantages of Sliding Bearing

The sliding bearing has a larger contact surface and lower surface pressure. Can use flexible shaft or shaft of other materials, such as aluminum alloy, carbon fiber, etc. Therefore, one of the many advantages of sliding bearings is a further reduction in weight. Since there is no mechanical rolling of hard friction parts and no collision of rolling elements, there will be less noise and vibration caused by the sliding operation.

Using linear sliding bearings, you can splice guide rails. The reason is that the movement of the sliding element is easier to pass through the rail seam than rolling elements. In all ball bearings, an important disadvantage related to the bearing material is the limit on the allowable speed and acceleration.

In contrast, sliding bearings made of engineering plastics have higher sliding speed and acceleration. Therefore, it can greatly improve its cycle time in many applications.