Top 3 Trends Impacting the Global Bearings Market Through 2021

- Share

- Issue Time

- Dec 17,2018

Summary

The top three emerging market trends driving the global bearings market according to research analysts are: Emergence of digitalization; Increased demand for integrated bearings; Emerging demand for application-specific bearings.

Top 3 Trends Impacting the Global Bearings Market Through 2021

The top three emerging market trends driving the global bearings market according to research analysts are:

- · Emergence of digitalization

- · Increased demand for integrated bearings

- · Emerging demand for application-specific bearings

Emergence of digitalization

The Internet of things (IoT) is discovering its pathway into the factory and has brought about an industrial revolution with the concept of Industry 4.0. This technology employs highly customized products in flexible manufacturing conditions. Companies are now in mid-way to networking their machinery, warehousing systems, and equipment worldwide. The accompanying global digitalization is marching at a mammoth speed. Digitalization involves components that can identify and transmit conditional information. Rolling bearings play a critical role as they are used for guidance and positioning of supporting process in forces and movements.

The Internet of things (IoT) is discovering its pathway into the factory and has brought about an industrial revolution with the concept of Industry 4.0. This technology employs highly customized products in flexible manufacturing conditions. Companies are now in mid-way to networking their machinery, warehousing systems, and equipment worldwide. The accompanying global digitalization is marching at a mammoth speed. Digitalization involves components that can identify and transmit conditional information. Rolling bearings play a critical role as they are used for guidance and positioning of supporting process in forces and movements.

Rolling bearings are now highly configured with sensors, actuators, control elements, and software components to implement flexible digitalization in the factory. The objectives range from continuous condition monitoring to independent location solution in response to bugs or active process control based on data taken from the bearings.

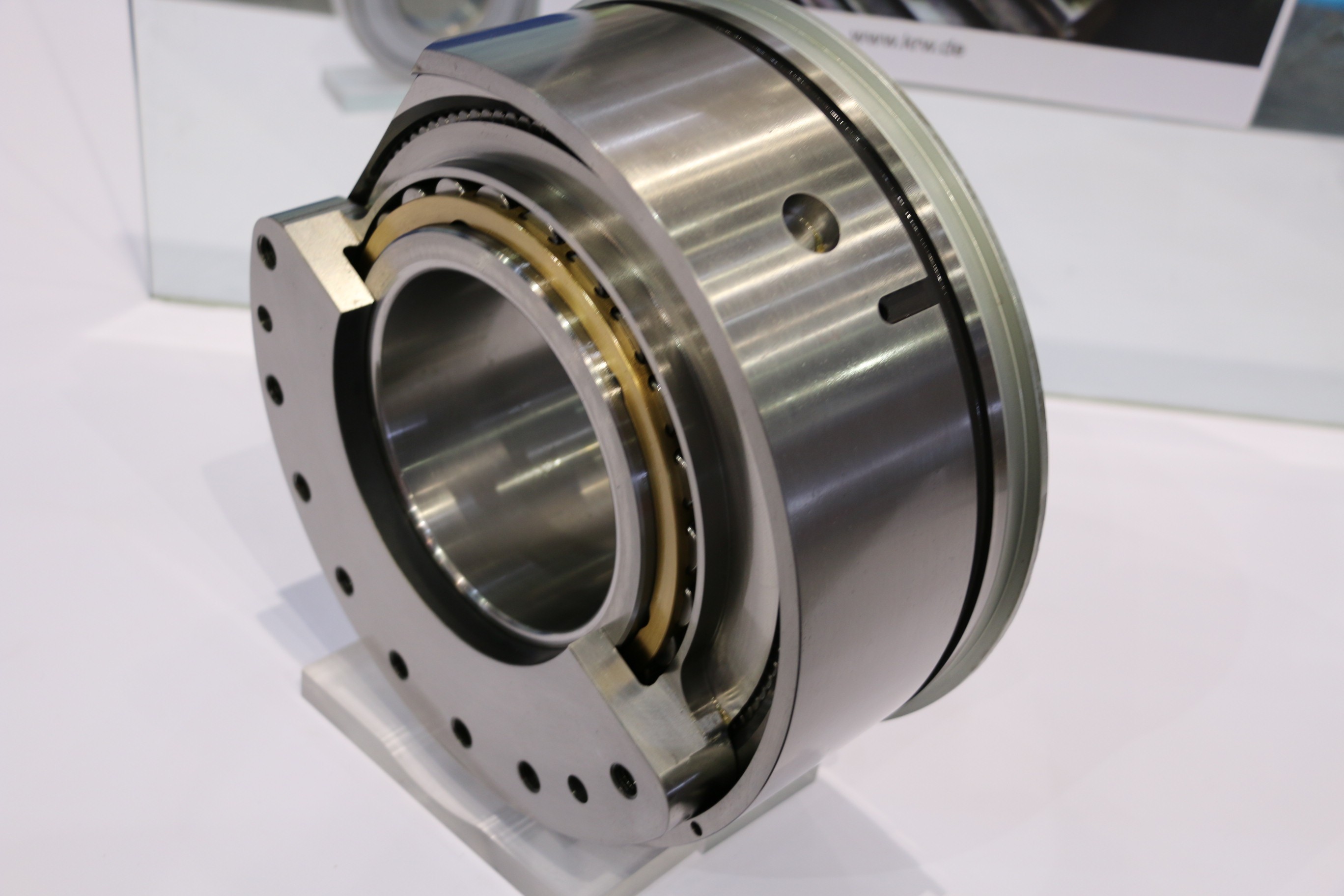

Increased demand for integrated bearings

Integrated bearings are special types of bearings with a hard payload, which improves the performance of rotating systems. The multiple-groove outer design layout limits the geometrical flaws and reduces torque, giving a performance improvement. The surrounding parts of the bearing work as an internal component of the bearing design. Such types of bearings are developed to minimize the number of bearing components in the final assembled product.

Integrated bearings are special types of bearings with a hard payload, which improves the performance of rotating systems. The multiple-groove outer design layout limits the geometrical flaws and reduces torque, giving a performance improvement. The surrounding parts of the bearing work as an internal component of the bearing design. Such types of bearings are developed to minimize the number of bearing components in the final assembled product.

“These bearings reduce the equipment cost, increase reliability, involve ease of installation, and boost service life. Integrated bearings are widely being adopted in the automotive and aerospace industries as measures to help optimize their production and drive efficiency in these industries,” says Raghav.

Emerging demand for application-specific bearings

Activities to protect the environment are gaining worldwide momentum. The bearing industry is shifting to developing new types of application specific bearings for the wind energy industry. Wind turbines require maintenance free and high-quality bearings that save energy and reduce carbon emission.

Activities to protect the environment are gaining worldwide momentum. The bearing industry is shifting to developing new types of application specific bearings for the wind energy industry. Wind turbines require maintenance free and high-quality bearings that save energy and reduce carbon emission.

This emerging trend towards clean energy will provide an opportunity for growth of the bearings industry during the forecast period. This should also translate into high demand for large bore anti-friction bearings in the manufacturing and heavy machinery units.