2020 Complete Information of Linear Bearing [Right Now]

- Share

- Issue Time

- Sep 4,2019

Summary

Linear bearing is a linear motion system with high precision, low cost, and low friction resistance. They combined with the guide shaft.

![2020 Complete Information of Linear Bearing [Right Now]](https://icdn.tradew.com/file/201804/1572758/jpg/7131009.jpg?x-oss-process=image/quality,Q_90)

2020 Complete Information of Linear Bearing [Right Now]

Linear bearing is a linear motion system with high precision, low cost, and low friction resistance. Metal linear bearing is a linear motion system produced at low cost for use with cylindrical shafts with infinite stroke. Widely used in sliding parts of precision machine tools, textile machinery, food packaging machinery, printing machinery, and other industrial machinery.

They combined with the guide shaft to achieve infinite linear motion using the rolling motion of the ball.

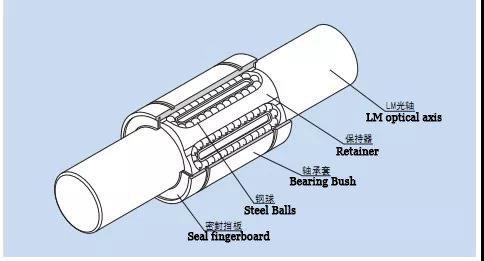

Linear bearings construction

Linear bearing process

The linear bearing has a steel ball-bearing cage inside the outer ring, and the cage has a number of rolling balls. The two ends of the retainer have a sealing gasket retainer ring. And there are notched windows in the straight track direction of each steel ball-bearing force. Therefore, this part makes the steel ball under load make rolling contact with the shaft and move relatively with a very low friction coefficient.

Therefore, the linear ball bearing is the most suitable bearing for mechanical equipment, automatic equipment, energy-saving equipment, and so on.

Straight-line linear bearing classification

1. According to materials:

Housing: stainless steel, bearing steel, aluminum alloy (with seat linear bearing);

Cage: resin, stainless steel, bearing steel;

Surface treatment: chrome plating, nickel plating, surface anodizing (linear bearing external fixing seat), etc.

2. Classification according to specifications:

Bearing classification according to bearing specifications. The plain bearings have two series, namely LM and LME series, whose code name is LM series has wide applications in Asia, southeast Asian countries, Japan, South Korea, China, and so on. With the metric dimension as the standard, the outer diameter tolerance of the straight spool is generally h7.

LME series have wide applications in Europe, the United States, Germany, Italy, and other regions. Hence, standard in inch size, but also in metric size. The outer diameter tolerance of the straight shaft is g6. Also, the structure of the two series is roughly the same, except that the size is different and the aperture tolerance is different.

3. By shape:

1): Straight cylinder type (the shape is like a cylinder, and people usually install it with a clamping spring, which is for small size installation)

2): Flange type (end or middle mounting flange, people can install it with screws. As well as, flange generally has three types which are circular, square, and cut edge type)

3): Opening type (the shape is like a straight tube, with the axial cutting seam on the outside, which is for occasions requiring clearance adjustment, including large opening and small opening type)

4. By bearing performance:

1): Generic (use for general performance requirements)

2): Supertype (long life and large load performance requirements)