How to Choose High-speed Motor Bearings Properly

- Share

- Issue Time

- Feb 22,2021

Summary

Motor bearings are key components that support the normal operation of motors. vertical motors and horizontal motors should choose different bearings.

How to Choose High-speed Motor Bearings Properly

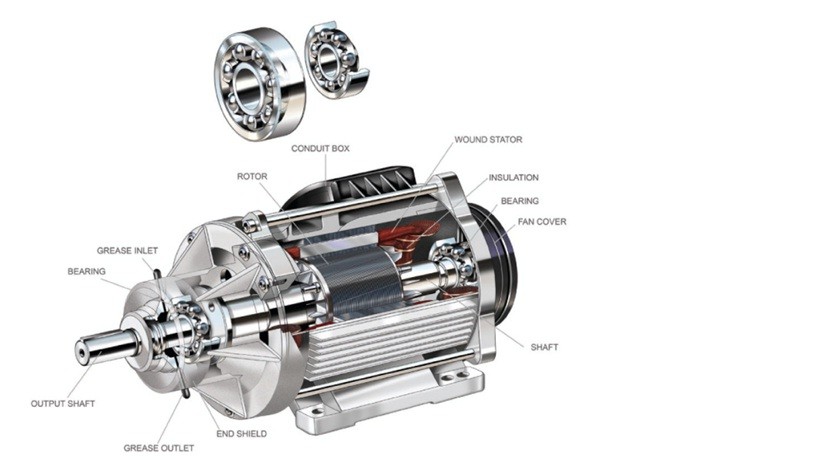

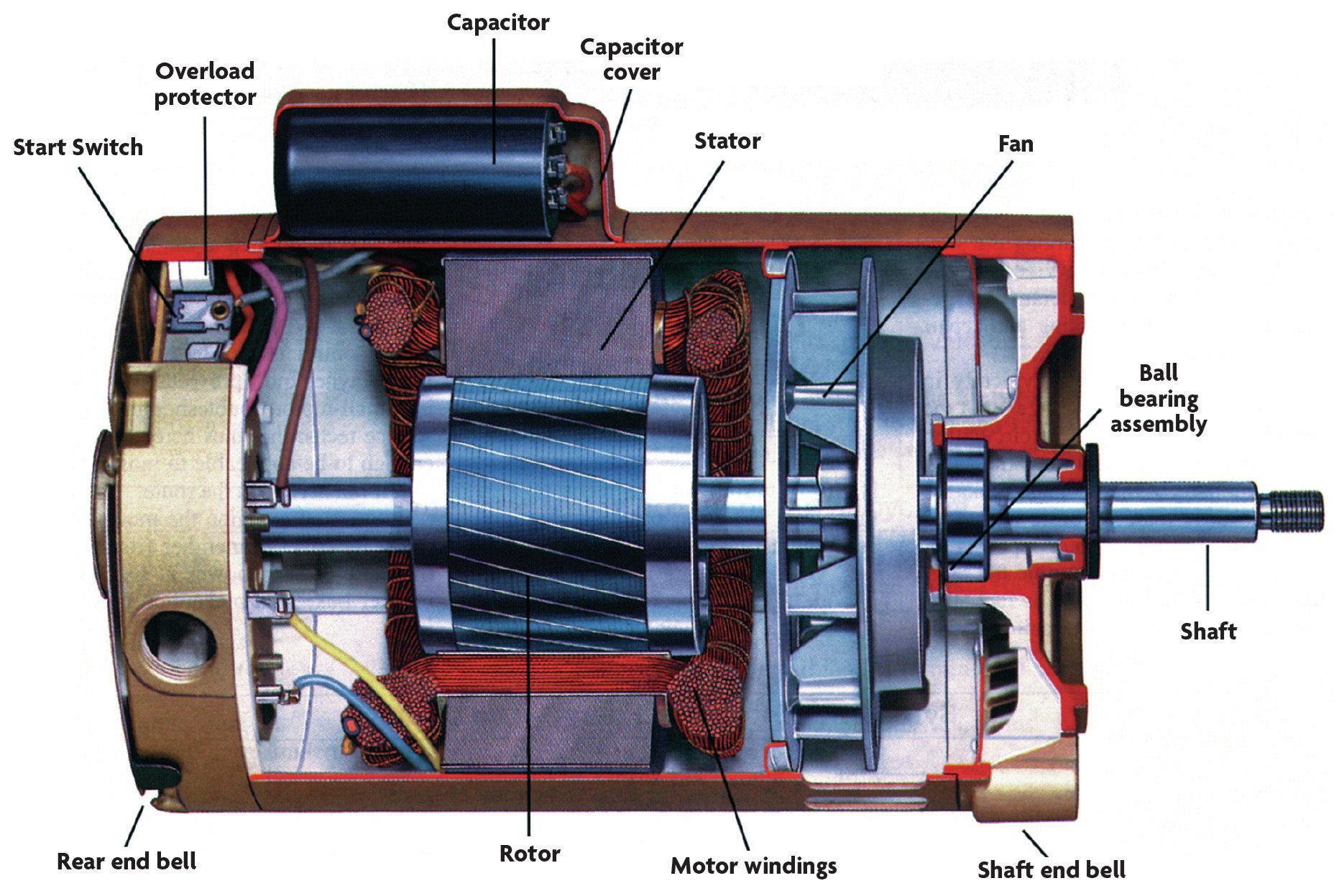

Horizontal motor bearings configuration

You should use a ball bearing and a column bearing as far as possible at both ends of the horizontal motor. Choosing a ball bearing and a cylindrical bearing can avoid the disadvantages of the balls squeezed after the bearing heats up. In order to solve heating and noise problems at the limit speed after replacing ball bearings with cylindrical bearings. Use light series column bearing and place it on the outer fan end. In this way, the cooling condition is good, it can also submerge and the bearing noise by the fan noise.

If the power of the 2-pole motor is larger, the bearing model used is larger. When the light series column bearing is also difficult to meet the requirements of the limit speed, you can use thin oil as the bearing grease.