How to Distinguish Deep Groove Ball Bearing Series

- Share

- Issue Time

- Jun 9,2022

Summary

Bearing vibration refers to the elastic deformation of bearing parts changing with time and all other movements deviating from the theoretical position except those necessary for bearing function.

Bearing vibration refers to the elastic deformation of bearing parts changing with time and all other movements deviating from the theoretical position except those necessary for bearing function. It is divided into vibration acceleration (DB) and vibration velocity (U m/s). The vibration acceleration is assessed in three levels: Z, Z1, Z2, and Z3. Level Z is the basic level, and Z1, Z2, and Z3 represent the bearing vibration level from low to high. See Table 7 for specific requirements. Because the vibration velocity measurement can better reflect the bearing processing level and the internal quality of the bearing, it is the most common.

Bearing grades B, C, D, e, G and P2, P3, P4, P5, P6, P0

Extreme value level of vibration acceleration level: divided into z1\z2\z3\z4 extreme value level of vibration speed level: divided into two commonly known noise levels above v1\v2\v3\v4. In addition, there are operating temperature levels, divided into s0\s1\s2\s3\s4. The last one should be the bearing level you want to know. Scientific name: tolerance level is divided into p0\p6\p6x\p5\p4\p2\. Sp\up is used for spindle bearings of precision machine tools. In this way, the common practice is p0\p6\p5\p4\p2. The old code is g\e\d\c\b. (ranking from low to high) generally, there are few production participants who can reach level P2, so level P4 can be regarded as the highest level

Full solution of NSK bearing model pre-code and post code (prefix and suffix)

NSK bearing model suffix full solution NSK bearing model is composed of basic code, pre-code, and postcode. The basic code represents the bearing series (including type) inner diameter dimension and contact angle; The leading code indicates a specific bearing; The postcode is a supplementary code added after the basic code of the bearing when the structural shape, dimension, material, seal, cage, tolerance, clearance, heat treatment, lubrication, technical requirements, etc. of the bearing are changed.

NSK bearing model front code

F - deep groove ball bearing with flange outer ring (applicable to D less than 10mm), for example, f605.

HR - high load tapered roller bearing, for example, hr30207j.

MF - deep groove ball bearing with flange outer ring of a specific size (D is less than 10mm), for example, mf52.

Mr - deep groove ball bearing of a specific size (applicable to D less than 10mm), for example, mr31.

NSK bearing model postcode

(1) Internal structure

https://www.sunbearing.net/n1871441/INTRODUCTION-of-608-BEARING.htm

A - bearing with an internal design different from the standard.

A - angular contact ball bearing, with a contact angle of 30 °.

A5 - angular contact ball bearing, with a contact angle of 25 °.

B - angular contact ball bearing, with a contact angle of 40 °.

C - angular contact ball bearing, with a contact angle of 15 °.

C - tapered roller bearing, with a contact angle of 20 °.

D - tapered roller bearing, with a contact angle of 28 °.

C. Ca (with brass solid cage), CD (with pressed cage) - high load self-aligning roller bearing.

E - high load cylindrical roller bearing.

H - high load thrust self-aligning roller bearing.

J - the small end diameter, angle, and outer ring width of the outer ring raceway of tapered roller bearing are consistent with ISO regulations.

(2) Material

G - ferrule, rolling element is carburized steel. H - ferrule, rolling element is stainless steel.

(3) Holder

M -- copper alloy solid cage T -- synthetic resin cage. W - pressed cage V - no cage.

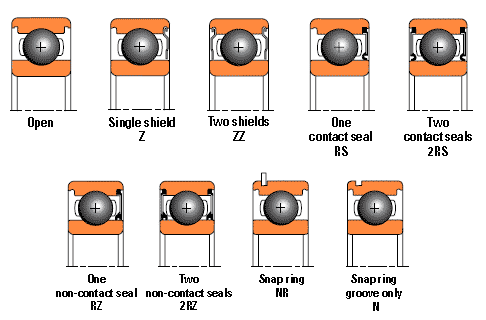

(4) Sealing ring, dust cover

Z. ZS - one side with steel plate dust cover. ZZ, ZZ - with steel plate dust cover on both sides.

D. Du - one side with contact rubber sealing ring. DD, DDU - contact rubber sealing ring on both sides.

V - one side with a non-contact rubber sealing ring. VV - with non-contact rubber sealing ring on both sides.

(5) Ferrule shape

K - conical hole, taper 1:12. K30 - conical hole, taper 1:30.

E - there is a cut or oil hole on the ferrule. E4 - outer ring with oil groove and oil hole.

N - outer diameter of the outer ring with stop groove. NR - outer diameter of the outer ring with stop groove and stop ring.

(6) Fit and pad

DB - back-to-back pair installation. DF - face-to-face installation in pairs. DT - installed in series in pairs.

+K - outer ring with gasket+ L - inner ring with gasket+ KL - inner and outer rings with gaskets.

(7) Clearance

C1 - radial clearance of radial bearing, smaller than C2 clearance.

C2 - radial clearance of radial bearing, smaller than the standard clearance.

CN (omitted) - Radial Standard clearance of the radial bearing.

C3 - radial clearance of radial bearing, larger than the standard clearance.

C4 - radial clearance of radial bearing, larger than C3 clearance.

C5 - radial clearance of radial bearing, larger than C4 clearance.

CC1 - radial clearance of cylindrical roller bearing (not interchangeable), smaller than that of CC2.

CC2 - radial clearance of cylindrical roller bearing (not interchangeable), smaller than the standard clearance.

CC -- Radial Standard clearance of cylindrical roller bearing (not interchangeable).

CC3 - radial clearance of cylindrical roller bearing (non-interchangeable), larger than the standard clearance.

CC4 - radial clearance of cylindrical roller bearing (not interchangeable), larger than that of CC3.

CC5 - radial clearance of cylindrical roller bearing (not interchangeable), larger than that of CC4.

MC1 - radial clearance of small and micro ball bearing, smaller than that of MC2.

MC2 - radial clearance of small and micro ball bearing, smaller than that of MC3.

MC3 - radial clearance standard clearance of small and micro ball bearings.

MC4 - radial clearance of small and micro ball bearing, larger than that of MC3.

MC5 - radial clearance of small and micro ball bearing, larger than that of MC4.

MC6 - radial clearance of small and micro ball bearing, larger than that of MC5.

Cm -- radial clearance of deep groove ball bearing and cylindrical roller bearing for the motor.

CT - radial clearance of cylindrical roller bearing for the motor.

(8) Tolerance class

P0 (omitted) - the tolerance grade conforms to grade 0 specified in the JIS standard.

P6 - the tolerance grade conforms to grade 6 specified in the JIS standard.

P6x - the tolerance grade conforms to grade 6x specified in the JIS standard.

P5 - the tolerance grade shall conform to grade 5 specified in the JIS standard.

P4 - the tolerance grade conforms to grade 4 specified in the JIS standard.

P2 - the tolerance grade conforms to grade 2 specified in the JIS standard.

(9) Special specifications

X26 - the service temperature is limited to below 150 ℃.

X28 - the service temperature is limited to below 200 ℃.

X29 - the service temperature is limited to below 250 ℃.

S11 - self-aligning roller bearing, the service temperature is limited below 200 ℃