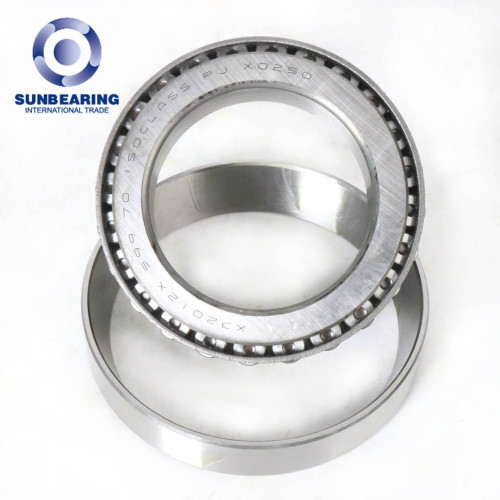

SUNBEARING 30314 Tapered Roller Bearing Silver 70*150*35mm Chrome Steel GCR15

- Price

- US $9.85

- Model

- 30314

- MOQ

- 1 piece

Item specifics

- Color

- Silver

- Service

- OEM Service

- Sample

- Available

- MOQ

- 1

Review

Description

Product Description

Tapered Roller Bearing 30314 | |

|---|---|

Specification | |

Design Units | Metric |

Structure | Roller Bearing |

Weights | 3.04kgs |

Cage Material | Steel cage |

Material | Chrome Steel GCR15 |

Ball Type | Carbon chromium steel |

Seals Type | Metal Seals |

Certificate | ISO9001:2008 |

Advantage | Bearing capacity of rolling mills, mines, and steel mills. |

Number of Rows | Single |

Dimensions | |

d-Bore Diameter | 70mm |

D-Outer Diameter | 150mm |

Precision Rating | P5 P6 P4 P2 P0 |

Clearance |

C2 C3 C4 C5 C0 |

H-Total Width | 35mm |

Basic Load Ratings | |

Cr Dynamic Load Rating | 223000N |

C0r Static Load Rating | 262000N |

SUNBEARING Metric taper roller bearing priced cup & cone together 70mm inside x 150mm outside x 35mm width

SUNBEARING Taper roller bearings have tapered inner and outer ring raceways between which tapered rollers are arranged. The projection lines of all the tapered surfaces meet at a common point on the bearing axis. Their design makes taper roller bearings particularly suitable for the accommodation of combined (radial and axial) loads.

Taper roller bearings are generally separable, i.e. the cone, consisting of the inner ring with roller and cage assembly, can be mounted separately from the cup (outer ring).

SUNBEARING taper roller bearings have the logarithmic contact profile that provides optimum stress distribution over the roller/raceway contacts. The special design of the sliding surfaces of the guide flange and large roller ends considerably promote lubricant film formation in the roller end/flange contacts. The resulting benefits include increased operational reliability and reduced sensitivity to misalignment.