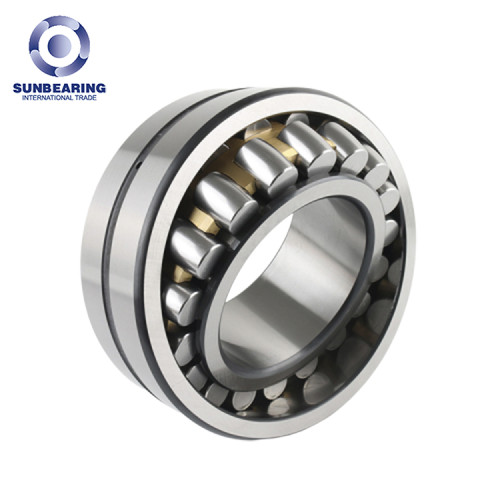

22213-EK Spherical Roller Bearing with Tapered Bore 65*120*31mm SUNBEARING

- Model

- 22213-EK

Item specifics

- Color

- Silver

- Inner Diameter

- 65 mm

- Outer Diameter

- 120 mm

- Width

- 31 mm

Review

Description

22213-EK Spherical Roller Bearing with Tapered Bore 65*120*31mm SUNBEARING

|

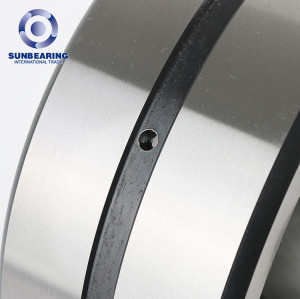

Bore diameter:

|

65 mm

|

Basic dynamic load rating

|

198 kN |

|

Outside diameter:

|

120 mm

|

Basic static load rating

|

216 kN |

|

Overall width:

|

31 mm

|

Fatigue load limit

|

24 kN |

|

Rows of Rollers

|

Double

|

Reference speed

|

5000 r/min |

|

Outer ring type:

|

Unsplit

|

Limiting speed

|

7000 r/min |

|

Radial clearance class

|

C3 Internal Clearance(Higher than Cn)

|

Mass

|

1.5 kg |

|

Closure type:

|

Open

|

r1,2 Tapered bore, taper 1:12 |

min. 1.5 mm |

Material | Chrome Steel | K | 3 mm |

Cage Material | Sheet Steel | Da | max. 111 mm |

Bore | K - 1:12 Tapered Bore (Standard for Most Types) | ra | max. 1.5 mm |

22213-EK Bearing Short Description

22213EK Spherical Roller Bearing 65x120x31

Spherical Roller Bearings are manufactured for the most demanding bearing applications. Manufactured using 2 rows of rollers using a common spherical outer raceway and two inner ring raceways they are self-aligning and therefore insensitive to shaft misalignment, deflection, or bending.

- Bore Type: Tapered Bore - Adaptor Sleeve Require: H313

22213-EK Spherical Roller Bearing Description

- Bearing is self-aligning

- Insensitive to angular misalignment

- Accommodates combined loads

- Three-piece cage so roller sets can operate independently of each other

- Produced in the cylindrical and tapered bore

- Bearings for vibratory applications available

22213-EK Bearing Application

Spherical Roller Bearing Clearance

For the installation axial clearance of the spherical roller bearing, it can be adjusted with the adjusting nut on the journal, the adjusting washer and the thread in the bearing seat hole, or the pre-tensioned spring.

The size of the axial clearance is related to the arrangement of the bearing, the distance between the bearings, and the material of the shaft and the bearing seat, and can be determined according to the working conditions.